Photoetching offers the flexibility to produce prototype quantities and large production runs while maintaining tight tolerances without the high tooling costs and long lead times.

Shaped parts are produced by combining photoetching, which is used for stamping, with cost-effective or universal tools used for forming. Heat treatment is possible to improve spring qualities.

Our production facilities are certified according to the following standards:

Thanks to our global network, we deliver quickly and at highly competitive conditions!

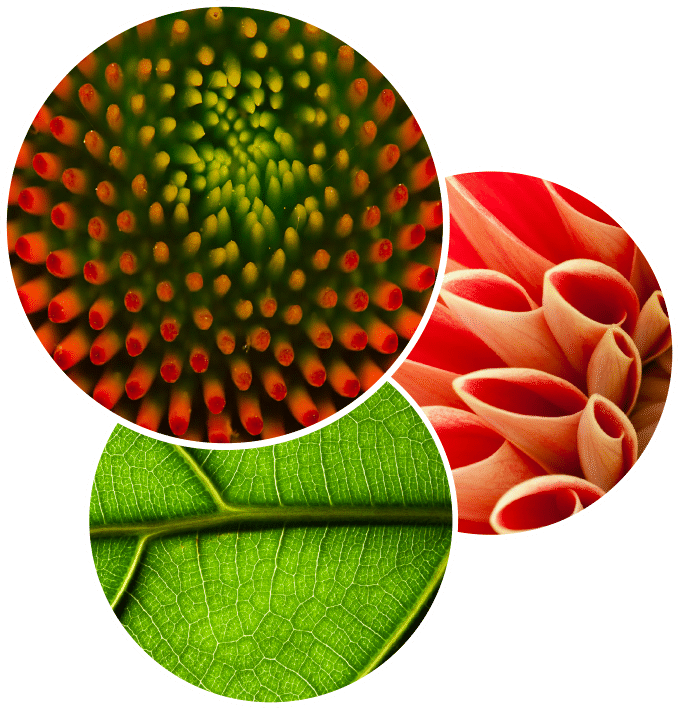

Precise, functional, and economical – the combinations found in nature are our inspiration.

s.m.k. GmbH

Floraweg 1a

5737 Menziken

Schweiz

T +41 41 740 56 40

info@smk-technik.ch

© s.m.k. GmbH

Legal Notice | Privacy Policy | AEB | VLB