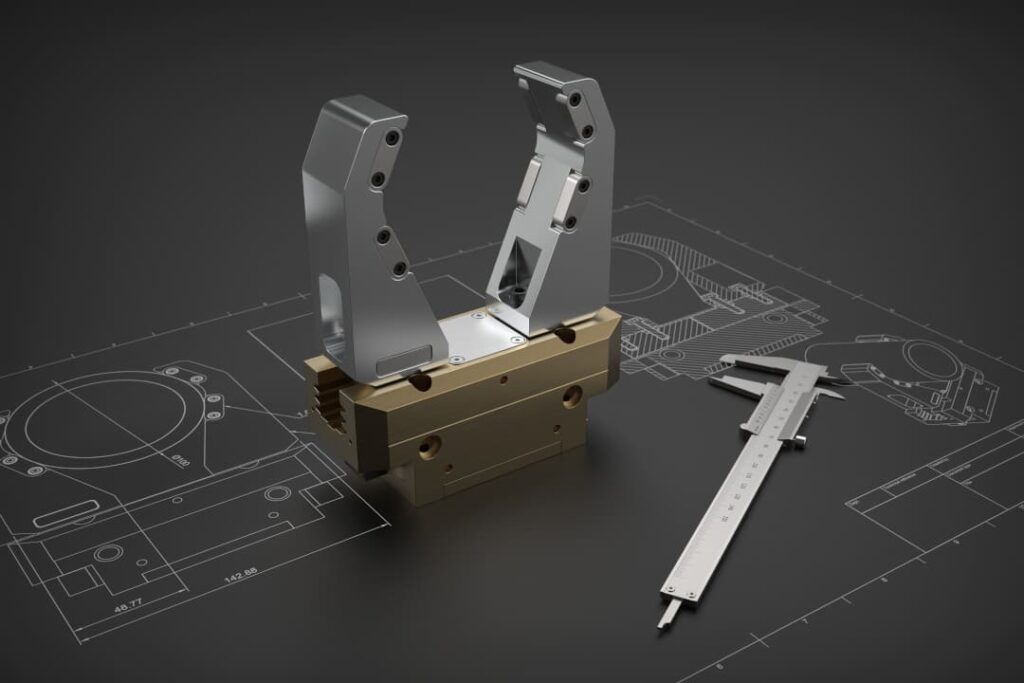

Technical metals – precision components in platinum, silver, gold & alloys for industry and R&D. From prototypes to series production.

As a specialist in precious and technical metals, SMK is your partner for the supply of semi-finished products, as well as turned and milled parts made from various precious metals, including precious metal recycling and precious metal management.

SMK combines cross-industry expertise with many years of experience and supplies a wide range of products, including semi-finished materials such as sheets, precision tubes, and fine wires. Additionally, we provide precision components, metal flat and shaped parts for medical technology, optics, aerospace, measuring instruments, and various devices made from silver, gold, platinum, titanium, brass, stainless steels, magnesium, palladium, and their alloys. This portfolio includes components for instruments, sensors, implants, and many other products.

Medical Technology

Electronics Industry

Aerospace

Chemical Industry

Jewelry Manufacturing

Mechanical Engineering

Development of sterilizable components for medical devices

Manufacturing durable and highly conductive contact components

Certainly, you may have many questions regarding high-precision turned and milled parts made of precious metals and our CNC services—whether about specific requirements, materials used, or areas of application. The manufacturing of high-precision turned and milled precious metal parts is a complex process that offers tailored solutions for a wide range of applications. To provide you with a comprehensive insight into this topic, we are ready to answer the most frequently asked questions.

These components are manufactured by precise CNC turning and milling of precious metals such as gold, silver, platinum, or palladium.

The abbreviation “CNC” stands for “Computerized Numerical Control,” which means “computergesteuerte numerische Steuerung” in German. In CNC machining, computers control machines like mills and lathes to automatically process workpieces with high precision.

Gold, silver, platinum, and palladium are the preferred materials for turned and milled parts because they offer outstanding properties.

Turned and milled precious metal parts are used in various industries, including jewelry manufacturing, watchmaking, electronics, medical technology, and aerospace, where precision CNC machining is required.

High corrosion resistance, excellent electrical conductivity, good mechanical properties, and an attractive aesthetic appearance.

Manufacturing is typically done through CNC machining, which enables highly precise turned and milled parts.

With modern CNC technologies, very tight tolerances of just a few micrometers can be achieved during manufacturing.

Turned and milled precious metal parts can be polished, gold-plated, rhodium-plated, matte-finished, or treated with other surface finishes to achieve the desired optical and functional properties.

Quality assurance is carried out through our CNC service, which includes visual inspections, dimensional checks, and material analyses.

Production ranges from small prototypes to large series, with our capacities flexibly adapting to customer requirements.

CNC-manufactured turned and milled precious metal parts can be individually packaged or shipped in batches according to customer needs to ensure safe and efficient handling.

Our production facilities are certified according to the following standards:

Numerous downstream industries rely on our high-quality metals.

Precise, functional, and economical – the combinations found in nature are our inspiration.

s.m.k. GmbH

Floraweg 1a

5737 Menziken

Schweiz

T +41 41 740 56 40

info@smk-technik.ch

© s.m.k. GmbH

Legal Notice | Privacy Policy | AEB | VLB