Electronic manufacturing services along the value chain: from engineering, consulting, procurement, production, testing, and assembly to shipping – EMS services all from one source.

As an experienced partner in EMS services and electronic manufacturing with our own production sites worldwide, we offer complete contract manufacturing for electronic assemblies and device assembly. We are your partner along the value chain: from engineering, procurement, production, testing, assembly to after-sales service.

EMS means comprehensive collaboration with customers and suppliers, quick responses, short process times, and holistic logistics. This enables us to deliver competitive prices for the production and development of your electronic assemblies and devices, all while meeting the highest quality standards.

The foundation for successful EMS services

The basis of every successful electronic manufacturing process and a central part of our EMS services is a well-thought-out engineering phase. Our team of experienced engineers supports you in the development and optimization of your products. We analyze the requirements of your electronic assemblies and evaluate potential designs for cost-effectiveness and manufacturability (Design for Manufacturing, DFM).

Innovative solutions for your electronic manufacturing

Using state-of-the-art CAD software and simulation tools, we ensure that your products can be produced technically flawlessly and cost-effectively. Additionally, we advise you on material selection and the integration of new technologies to maximize the performance and longevity of your products. Our goal is to develop innovative solutions that secure your competitive advantage.

Your partner for tailored electronic solutions

Our EMS services begin with comprehensive consulting to understand your specific requirements. Together, we develop individual concepts tailored to your goals and needs. From the initial idea to implementation, we are your reliable partner.

Efficiency and cost optimization in electronic manufacturing

Our consulting covers technical aspects and strategic considerations such as optimizing production costs, delivery times, and logistics processes. Thanks to our many years of experience in electronic manufacturing, we provide sound recommendations to help you implement your projects efficiently and successfully.

High-quality components for your EMS services

Our procurement team handles the sourcing of all necessary components and materials for your electronic assemblies. We work with a global network of vetted suppliers to ensure high-quality parts at competitive prices.

Transparent and flexible procurement processes

A special focus of our EMS services is securing supply chains. We collaborate with strategic partners to avoid bottlenecks and ensure the availability of critical components. Our procurement processes are transparent and flexible, allowing us to respond quickly to changes.

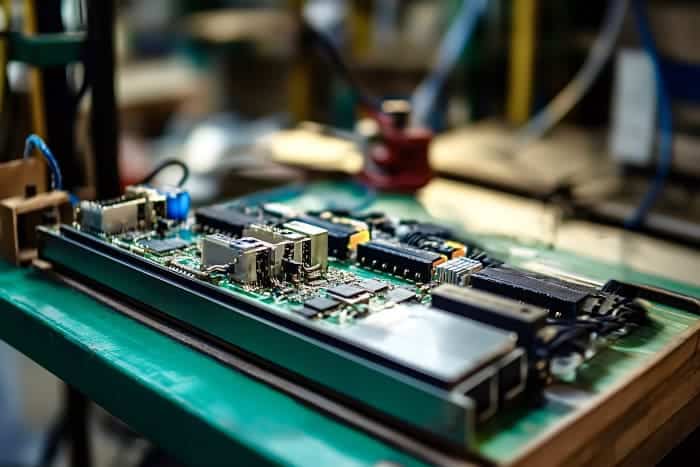

Precision and quality in electronic manufacturing

Our EMS services include the production of electronic assemblies and devices in state-of-the-art production facilities. Whether prototypes, small batches, or large series – we implement your projects according to the highest quality standards.

Flexibility and cutting-edge technologies

Our production processes include automated PCB assembly (SMT and THT), coating, potting, and mechanical processing. Every assembly undergoes strictly controlled manufacturing steps to ensure maximum precision and reliability.

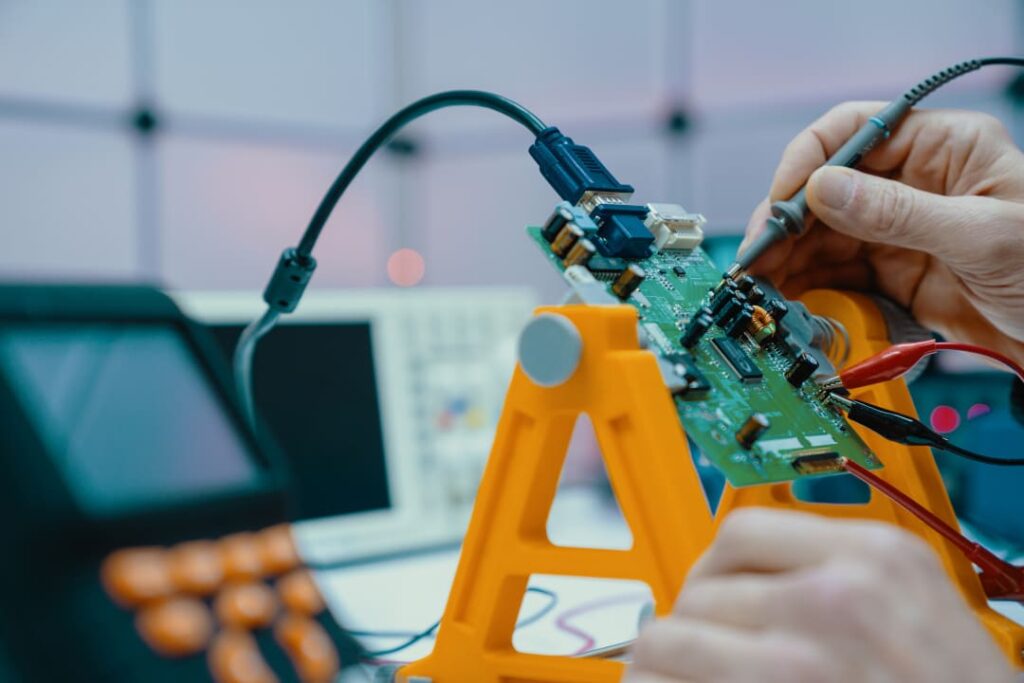

Comprehensive quality assurance in electronic manufacturing

Quality is a central part of our EMS services. All products undergo extensive testing to ensure your electronic assemblies meet the highest requirements. Our procedures include optical inspections (AOI), in-circuit tests (ICT), and individual functional tests.

Reliability under extreme conditions

Additionally, we offer environmental simulations where your products are exposed to extreme conditions such as heat, cold, or vibration. This ensures that your assemblies perform reliably even in the most demanding environments.

Efficient assembly for EMS services

In the assembly phase, we combine all components into finished devices. Our teams work precisely and efficiently to ensure every product meets the highest quality standards.

Customized packaging solutions

Additionally, we offer tailored packaging solutions to optimally prepare your products for shipping. Our assembly lines are flexibly configurable, allowing us to efficiently execute projects of any size.

Durability and reliability for your electronic manufacturing

Our services do not end with delivery. With our comprehensive after-sales service, we support you even after project completion. We offer repairs, spare parts procurement, and technical support to maximize the lifespan of your products.

Preventive maintenance for maximum efficiency

Our preventive maintenance services help detect and resolve potential failures early. This reduces your operating costs and increases the availability of your products.

Medical Technology

Automotive

Industrial Automation

Telecommunication

Renewable Energy

Mechanical Engineering

Development and series production of a complex assembly with strict quality requirements.

Prototype production and subsequent series manufacturing of a durable control unit.

An EMS (Electronic Manufacturing Service) is a company that manufactures electronic assemblies and devices according to its customers’ specifications.

EMS companies provide services such as design, prototyping, manufacturing, assembly, testing, and logistics for electronic assemblies and devices.

Working with an EMS provider allows customers to benefit from expertise, resources, and efficiency advantages without having to build their own manufacturing capacities.

Choosing the right EMS company depends on factors such as quality, reliability, experience, capacity, location, and cost.

EMS providers manufacture a wide range of products, including electronic assemblies, circuit boards, components, devices, and systems for various industries such as electronics, medical technology, automotive, and telecommunications.

EMS companies use a variety of technologies and manufacturing methods, including PCB assembly, surface mount technology (SMT), through-hole technology (THT), screen printing, soldering, testing, inspection, and packaging.

EMS providers offer support in product development through prototyping, design optimization, material sourcing, and consulting services.

Quality assurance is crucial to ensure compliance with quality standards, regulations, and customer requirements, and to guarantee customer satisfaction.

EMS companies are flexible and respond quickly to changing customer requirements by applying agile production processes, effective communication, and adaptability.

Current trends in the EMS industry include increasing miniaturization, integration of IoT and Industry 4.0 technologies, sustainability, digitalization of production processes, and global supply chain optimization.

Our production facilities are certified according to the following standards:

Wide manufacturing range, mature logistics, and reliable delivery dates!

Precise, functional, and economical – the combinations found in nature are our inspiration.

s.m.k. GmbH

Floraweg 1a

5737 Menziken

Schweiz

T +41 41 740 56 40

info@smk-technik.ch

© s.m.k. GmbH

Legal Notice | Privacy Policy | AEB | VLB